There’s something thrilling about watching your custom wardrobe design come to life—until installation day arrives. That’s when reality hits. All the careful planning and anticipation can unravel in a matter of hours if things go wrong. And when your wardrobe comes from overseas—say, a custom wardrobe from China—every step leading up to that day needs to be on point. Cross-border projects don’t forgive mistakes. Miscommunication, missed measurements, or overlooked details can easily turn a dream upgrade into an expensive hassle.

That’s why we’ve put together this no-fluff guide. It covers the most common mistakes people run into—many of which only show up once it’s too late—and gives you clear, practical ways to avoid them. From the drawing board to the final screw, here’s what you need to know to get your wardrobe installed right the first time.

The Foundation of Flawless Installation: Design & Planning

A flawless installation doesn’t begin on install day—it starts during the design phase. And when it comes to custom wardrobes, you usually only get one shot to get it right.

Pitfall: Skipping precision in measurements

Measuring once and hoping for the best? That’s a shortcut to frustration. Even small miscalculations can cause doors to jam, visible wall gaps, or an unsteady structure. Instead of relying on a basic tape measure, invest in a laser distance tool and measure multiple points—especially in older homes where walls and ceilings may not be perfectly straight. Always share these details with your China custom wardrobe manufacturer so they can adjust the build accordingly.

Pitfall: A rigid design that doesn't account for the future.

A rigid design that doesn’t account for the future can make your brand-new wardrobe obsolete as your lifestyle or family needs change. Smart design incorporates flexibility, so you should ask for adjustable shelves, height-adjustable hanging rods, and modular components that can be reconfigured down the line.

Pitfall: Forgetting about your actual wardrobe.

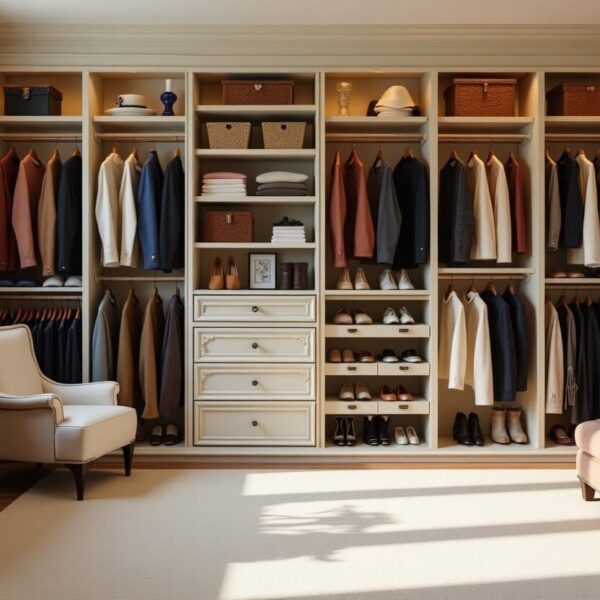

Forgetting about your actual wardrobe can result in a beautifully designed space with poor functionality. You may find that your long coats don’t fit, or there’s no dedicated space for shoes and accessories. The solution is simple: before designing, take inventory of your belongings. Categorize them and then build a design that perfectly accommodates your specific needs.

The Core of Quality: Materials & Internal Environment

The best design is only as good as its materials. In the world of custom wardrobes from China, quality is paramount.

Pitfall: Choosing cheap, low-grade materials.

Choosing cheap, low-grade materials will impact your cabinet over time, causing it to warp, discolor, or sag, which drastically shortens its lifespan. To prevent this, prioritize durability and performance by choosing quality materials like solid wood, multi-layer boards, or moisture-resistant panels. Always verify the brand, thickness (with an error tolerance of ≤0.5mm), and environmental certifications like E0 or ENF.

Pitfall: Overlooking lighting and moisture control.

Overlooking lighting and moisture control can lead to a dark cabinet that makes it hard to find clothes, and a damp interior that can lead to mold and mildew. To solve this, integrate LED strips or plan for sensor lights. Ensure there is adequate ventilation and that back panels are properly sealed, especially in humid climates.

Custom Wardrobe Installation Essentials

This is where magic happens. A methodical and careful approach is non-negotiable.

Pre-Installation Checklist

A methodical and careful approach to installation begins with a thorough pre-installation checklist. Before your installation team arrives, you should clean and protect the entire room. Once they are on site, take the time to re-verify the measurements and components with your installer, and count all parts and hardware to ensure everything has arrived and matches your order.

Have a project in mind? Send a message.

Get the catalog for free

The Installation Process

The installation process is a methodical series of steps. It begins with marking the cabinet’s footprint and leveling the area. Next, the main frame is assembled with solid connections, followed by securing all horizontal and structural panels for a stable core. After the main structure is in place, internal fittings like drawers and hanging rods are installed. The doors are then carefully mounted and adjusted for a perfect fit, and finally, the finishing touches like handles, lighting, and other hardware are added to complete the installation.

Installation Pitfalls & Solutions

Pitfall: Lack of structural support or improper fastening.

A lack of structural support or improper fastening can cause the entire unit to wobble or even tip over, posing a serious safety risk, especially for children. To prevent this, your installer must use the correct anchors, such as expansion bolts, for your specific wall type and a level to ensure the cabinet is perfectly straight and secure.

Pitfall: Poor joinery and hardware installation.

Poor joinery and hardware installation can result in an unstable cabinet, doors that don’t open smoothly, and a poor aesthetic finish. Professional installers use three-in-one connectors for stable joints. They also perform a load-bearing test (≥30kg) on drawer slides and ensure hinges are precisely aligned for a perfect fit.

Pitfall: Neglecting special scenarios.

Neglecting special scenarios can cause common issues, such as gaps in a built-in wardrobe that collect dust, or a top cabinet that warps due to expansion and contraction from temperature changes. To avoid this, you should leave a 10-15mm expansion gap for top cabinets and use anti-mold sealant to finish gaps in built-in units.

The Final Verdict: Your Acceptance Checklist

The work isn’t done until you’ve thoroughly inspected it. Use this checklist as your final line of defense.

- Check for Level and Plumb: All shelves and rods should be perfectly horizontal, and the entire cabinet should be vertical.

- Test Doors and Drawers: Open and close each door at least 20 times to test the hinges and soft-close mechanisms. Pull out drawers fully to check for smooth operation.

- Inspect Hardware: Confirm all screws are tight and that handles are securely and symmetrically mounted.

- Check Gaps and Joints: The gap between the cabinet and wall should be no more than ≤3mm, and door gaps should be uniform (2-4mm).

- Test Load-Bearing: Place heavy items on shelves and hanging rods to confirm stability.

- Inspect the Finish: Check for scratches, dents, and ensure the edge banding is smooth and perfectly sealed.

- Verify Functionality: Test all special accessories, from pull-out pant racks to lighting systems.

Why Trust NextHome Furnishing with Your Project?

While a successful DIY installation is possible, the safest and most efficient path is to partner with a professional.

At NextHome Furnishing, a leading China custom wardrobe manufacturer, we’ve dedicated over ten years to mastering every detail of the process. We understand the nuances of crafting and delivering custom wardrobes from China to clients worldwide.

As a trusted China custom wardrobe maker, we offer more than just high-quality cabinetry; we provide a seamless, end-to-end service, from meticulous design and production to professional installation support. We are your partner in turning your vision into a stunning reality.

Ready to start your dream project? Contact us today for a personalized design consultation.

Contact NextHome Now!

We are here to help you with your business needs. We have a team of experts who are always eager to help you.