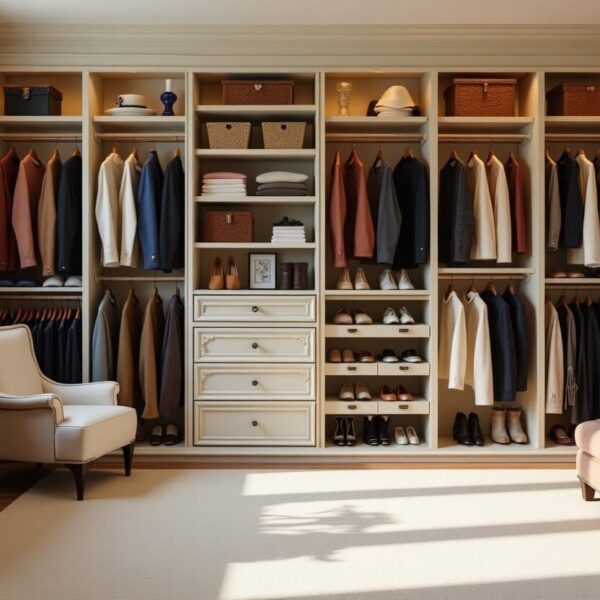

Navigating the world of custom cabinetry from China can feel like a high-stakes game for overseas buyers. Stories abound online, from claims of subpar quality to allegations of widespread corner-cutting by suppliers. While we won’t get into the specifics of these rumors about the Chinese cabinet manufacturing industry, as an international custom furniture brand with over two decades of experience rooted in China, we’re reminded of a local proverb: ‘When the forest is vast, every kind of bird can be found.’ This holds true not just for China’s furniture market, but for global markets too.

We believe that true success in sourcing comes from informed discernment. Drawing on real-world incidents from the Chinese market in recent years, this guide will illuminate common tactics used by less scrupulous cabinet manufacturers, helping you identify and steer clear of potential pitfalls.

Material Matters: 5 Sneaky Tricks Factories Use to Cut Corners

Some factories unfortunately compromise on materials to boost profits, which can lead to subpar products that might even pose health risks and reduce the lifespan of your home furnishings. Let’s delve into five subtle tactics employed by these manufacturers, complete with examples and practical advice to help you make informed choices.

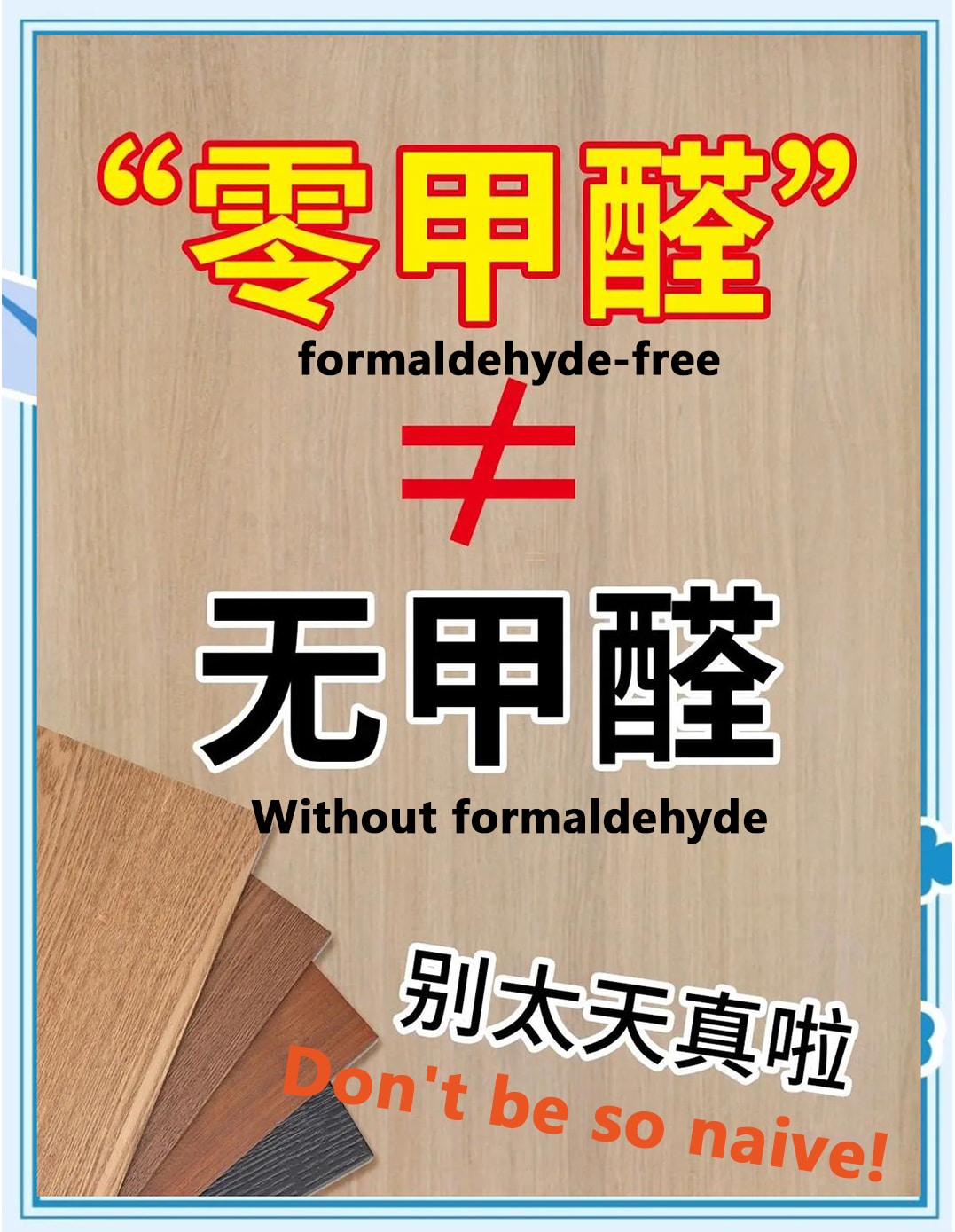

The Formaldehyde Fiasco: E0 Boards vs. The "Zero Formaldehyde" Sham

Formaldehyde, a common VOC in engineered wood adhesives, is largely unavoidable in wood products. However, excessive emissions can cause health issues. While some manufacturers misleadingly label products as “zero formaldehyde,” true zero is practically impossible for wood-based panels. The focus should be on low-emission standards. China’s GB 18580-2017 standard sets limits, with E0 (≤0.05 mg/L) being the highest environmental grade. Be wary of “zero” claims; for instance, China’s 2020 CCTV 315 program exposed furniture brands using E2-level boards despite “zero formaldehyde” claims. It’s advisable to prioritize E0-grade panels or internationally recognized low-emission certifications, and review material specification sheets that reference the official GB 18580-2017 standard.

Substrate Degradation: The "Solid Wood Veneer" Deception – 0.6mm vs. 1.2mm

“Solid wood veneer” offers an appealing aesthetic, but its thickness significantly impacts durability. Some manufacturers use veneers as thin as 0.6mm over cheaper cores, drastically shortening product lifespan and making them vulnerable to damage. For quality furniture and cabinetry, a thickness of 1.2mm or more is generally recommended for solid wood veneers, allowing for better durability and potential repairs. For example, in 2023, the U.S. Better Business Bureau received complaints about “solid wood” dining tables from Chinese suppliers where thin veneers cracked quickly. Similarly, Chinese investigative reporters found some domestic brands selling 0.5mm veneer boards as “premium thick veneer.” It’s helpful to clarify veneer thickness in writing, aiming for at least 1.2mm for optimal durability, and requesting cross-section samples or detailed material specifications.

OEM Branding: Identifying Fake Imported Hardware (Blum Authenticity Check System)

Hardware like hinges and drawer slides are crucial for cabinet function and longevity. Some manufacturers, particularly in China, might falsely claim to use “imported” or “German-made” hardware, even displaying reputable brand logos like Blum. Genuine imported hardware often features unique authenticity features, such as laser-engraved codes or QR codes verifiable on official brand websites. In 2022, Salice (Italy) cautioned against widespread counterfeit sales in China, and Blum encourages international buyers to scan their official codes. Relying solely on logos can be misleading. For major brands, consider requesting product verification codes or QR codes to cross-reference directly on the brand’s official website, and inquire about certificates of authenticity from the hardware supplier.

Environmental Certifications: FSC/PEFC Certificate Verification Guide

For those prioritizing sustainability, FSC and PEFC certifications confirm responsibly managed wood sources. Some manufacturers might inaccurately claim these certifications, displaying similar logos or applying “FSC-certified” labels when only a small component is certified. Both FSC (info.fsc.org) and PEFC (pefc.org/find-certified) maintain public databases where certificate authenticity and validity can be verified by company name, code, or product type. It’s advisable to verify the certificate number and ensure the listed company is the actual manufacturer. A global NGO, Earthsight, for example, exposed misuse of FSC certificates by Chinese wood exporters in 2021. Requesting the full FSC or PEFC certificate number and verifying it on the official database, cross-referencing with your manufacturer’s name, can be beneficial.

Quartz Stone Scam: 93% Quartz Content vs. Cheap Calcium Carbonate Filler

Quartz countertops are highly prized for their durability, stain resistance, and aesthetic appeal. The secret to their superior performance lies in a high concentration of natural quartz. Unfortunately, some unscrupulous manufacturers try to boost profits by substituting a significant portion of the quartz with cheaper fillers, most commonly calcium carbonate (limestone). This drastically compromises the countertop’s hardness, scratch resistance, and ability to withstand heat and acids, making it prone to chipping, staining, and losing its luster over time. Ideally, a high-quality quartz countertop should contain at least 93% natural quartz.

While visual inspection can be challenging, here are some practical ways to discern genuine quartz from diluted imitations:

- Density Test: Genuine quartz is significantly denser than calcium carbonate. If you have a sample, compare its weight to a known authentic quartz sample of the same size. If it feels unusually light, it might indicate a high filler content.

- Visual Cues: Look for small, evenly distributed specks of quartz crystals. Countertops with high calcium carbonate content often appear duller, less lustrous, and may feel softer to the touch.

- Scratch Test (using a knife or key): Gently scratch an inconspicuous area with a knife blade or a key. If a black mark appears but can be easily wiped away, it’s likely genuine quartz. If you see a clear scratch that leaves a white powder when wiped, it’s probably a lower-quality or fake product.

- Vinegar Test: Drop a small amount of white vinegar onto the surface. If it fizzes or bubbles after about five minutes, it suggests the presence of calcium carbonate (which reacts with acid), indicating a fake or poor-quality product. If there’s no reaction, it points to genuine quartz.

- Burn Test (using a lighter): Briefly hold a lighter flame to an inconspicuous area of the surface. If the area turns black but can be easily wiped clean, it’s likely genuine quartz. If the black mark is difficult or impossible to remove, it indicates a high resin or filler content.

- Soy Sauce Immersion Test: Drip some soy sauce onto the countertop and let it sit for a while. Genuine quartz should show no significant color absorption. If there’s noticeable permeation or staining, it suggests a porous, lower-quality, or fake product.

These deceptive practices are not uncommon. For example, in 2022, the U.S. Importers Association reported that over 30% of tested Chinese quartz samples contained less than 70% quartz with heavy calcium filler. A viral Douyin video in 2023 further highlighted this issue, showing a factory employee revealing “export-only” countertops filled with cheap powder and resin.

To safeguard your investment, it’s wise to stipulate a guaranteed quartz content of at least 93% in writing within your contract. Additionally, requesting material composition reports and performing a density comparison can provide further assurance.

Beyond the Board: 3 Cabinet Construction Cons Factories Hope You Never Discover

Beyond material quality, the construction methods used for your cabinets are equally vital for their longevity and performance. It’s the hidden details that can determine your cabinetry’s true durability. Here are three common factory practices that can subtly compromise your cabinets over time.

Have a project in mind? Send a message.

Get the catalog for free

The Back Panel Betrayal: Single-Sided vs. Double-Sided Moisture Protection

Even with beautiful cabinets, vulnerability to moisture can lead to issues like rot and mold. Some manufacturers, to reduce costs, use single-sided edge banding on back panels, leaving the hidden side exposed to wall moisture. In humid environments, this can lead to swelling, warping, and mold growth, impacting air quality and cabinet integrity. Opting for double-sided moisture-proof edge banding for all back panels is a beneficial choice. Requesting proof, like a 72-hour water immersion mold comparison test, can provide reassurance, especially in high-humidity areas.

The Thickness Deception: 18mm Carcass Boards vs. Cheap 16mm Imposters

The structural integrity of your cabinets relies on the thickness of the carcass boards. Some factories might use 16mm boards instead of the industry-standard 18mm, a seemingly small difference that significantly impacts structural integrity and load-bearing capacity. Thinner boards can lead to sagging shelves, loose doors, and compromised drawer function. Carrying a caliper to measure board thickness can be useful. Aim for 18mm thick boards throughout the cabinet carcass, and consider inquiring about load-bearing test data. Additionally, a 1mm edge band generally offers a more robust seal and flexibility compared to a thinner 0.4mm band.

The Structural Swindle: Laser Edge Banding vs. Hand-Applied Glue

The edge banding on your cabinets is critical for protecting against moisture and wear. Some factories use hand-applied glue edge banding, which can be prone to delamination and moisture penetration due to inconsistent bonds. This can lead to gaps, peeling edges, and damage from steam, humidity, and spills, particularly in high-moisture areas. Laser edge banding technology offers a superior, virtually seamless bond without a visible glue line. Inquiring about laboratory reports on steam penetration rates for different methods, or even performing a simple heat gun test on a sample, can help assess the quality of the edge banding.

Door & Drawer Secrets: Debunking "Solid Wood" Marketing Hype

“Solid wood” is often seen as the premium choice, but for custom cabinetry, especially door panels, other materials can offer advantages depending on the climate.

Humidity Reality: The Advantage of MDF Cores in Humid Climates

While “solid wood” is often lauded, MDF (Medium-Density Fiberboard) cores can offer superior stability and warp resistance for door panels in humid climates (e.g., Guangzhou’s 77% average annual relative humidity vs. Los Angeles’s 64%). For instance, some overseas importers reported receiving warped “premium hardwood cabinet doors” from China in humid U.S. Gulf Coast ports. Conversely, manufacturers using moisture-resistant MDF for cabinet doors often experience fewer shipping issues. Many high-end modern Chinese cabinet producers now utilize MDF cores, often with rigid thermofoil or lacquered finishes for enhanced moisture protection. Understanding material pros and cons relative to your climate, rather than solely relying on marketing hype, can lead to more practical and durable choices.

Hardware Lifespan: 200,000 Cycles vs. 500,000 Cycle Hinge Tests

Inexpensive hinges might claim durability but often only withstand 200,000 opening/closing cycles, significantly less than the 500,000 cycles offered by higher-quality hardware. Quality hardware is a valuable investment for cabinet longevity and smooth operation. When considering hardware, it’s beneficial to ask for hinge test reports (e.g., SGS or equivalent) indicating a minimum of 500,000 cycles, and to inquire about salt spray corrosion test videos or certifications for long-term performance, especially in kitchens and bathrooms.

Drawer Slide Secrets: Triple-Extension Ball Bearing vs. Cheap Two-Section

Two-section drawer slides offer limited access and load-bearing capacity compared to triple-extension ball-bearing slides, which provide full drawer access and robust performance. For smooth-operating drawers, even when fully loaded, triple-extension ball-bearing slides are generally preferred. Requesting 10kg load-bearing test data can help confirm their performance.

Installation Landmines: Details Even Contractors Miss

Even impeccably crafted cabinets can be compromised by poor installation, making attention to detail during this phase crucial.

Have a project in mind? Send a message.

Get the catalog for free

Laser Calibration: 0.5mm Error Standard vs. Common 3mm

Achieving precise alignment in cabinetry is key to a polished look. Some installers might have a more relaxed tolerance for error, sometimes allowing for 3mm or more in cabinet alignment, which can result in uneven door gaps, misaligned drawers, and visibly askew panels. For a truly perfect finish, aiming for laser calibration during installation, with a precision standard of 0.5mm or less, is highly recommended. This helps ensure plumb and aligned doors, uniform gaps, and seamless corners.

Kickboard Waterproofing: PVC Coating vs. Recycled Materials

The kick plate, at the base of your cabinets, serves as a crucial defense against moisture. Unfortunately, some projects might use less durable kick plates made from recycled materials, which can swell, deform, or rot when exposed to moisture, potentially compromising the cabinet’s structural integrity. Choosing kick plates with a proper PVC moisture-proof coating can offer enhanced durability. Requesting a 72-hour immersion comparison test result from the manufacturer can help confirm its long-term performance, protecting your investment from the ground up.

How We Build Awesome: Your Trusted Partner in Custom Cabinets

High-quality cabinetry starts with selecting the right partner. With decades of expertise in high-end OEM and custom manufacturing, we at NextHome Furnishing aim to blend Eastern craftsmanship with global standards. We strive to offer an experience built on transparency, quality, and truly exceptional custom cabinetry.

If you’re ready to bring your vision of perfectly tailored, high-quality home furnishings to life, with a focus on mitigating typical sourcing risks, we invite you to connect with NextHome Furnishing today. Let’s discuss your project and explore the difference that genuine craftsmanship and unwavering reliability can make.

Contact NextHome Now!

We are here to help you with your business needs. We have a team of experts who are always eager to help you.